By Donal Bourke, PEMAC Director of Sales.

Maintenance is an essential aspect of any business or organisation, and it is essential to ensure that equipment and machinery are operating optimally to prevent downtime and prolong their lifespan. To achieve this, many companies use maintenance management systems, which can either be CMMS (Computerised Maintenance Management System) software or ERP (Enterprise Resource Planning) software maintenance modules. While both solutions serve similar purposes, using a CMMS software solution can be a better alternative to using an ERP software maintenance module. In this blog, we will discuss why, and how to implement an interface between the CMMS software and ERP software.

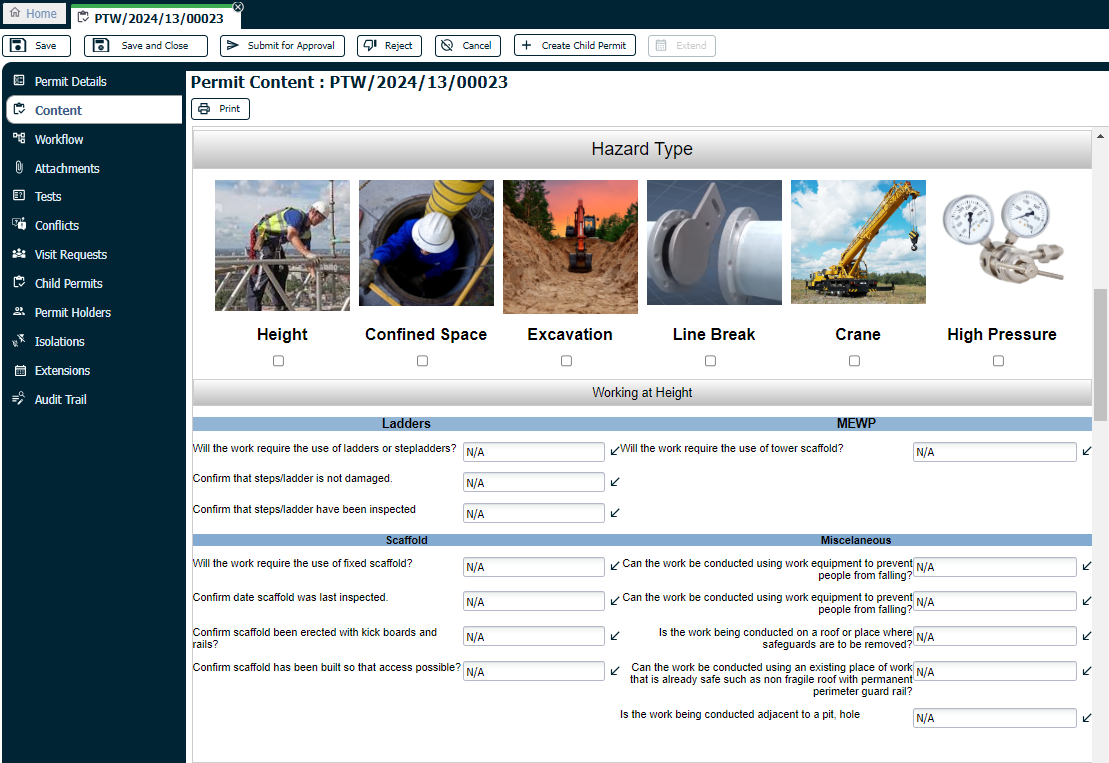

Firstly, it is important to understand what CMMS and ERP software are and how they differ. CMMS software is designed specifically for maintenance management and includes features such as work order management, asset management, inventory management, and preventive maintenance scheduling. On the other hand, ERP software is designed to manage all aspects of a business, including finance, supply chain management, human resources, and customer relationship management, with maintenance management being just one of its modules. While ERP software can handle maintenance management tasks, it is not specifically designed for this purpose, and it may lack the functionality required by maintenance professionals.

Using a CMMS software solution offers several benefits over an ERP software maintenance module. Firstly, CMMS software is easier to use and more intuitive for maintenance personnel as it is designed specifically for this purpose. Secondly, CMMS software provides more comprehensive reporting and analysis capabilities, allowing maintenance managers to identify trends and areas for improvement. Thirdly, CMMS software offers more flexibility when it comes to configuring and customising maintenance management workflows.

However, using both CMMS and ERP software can be beneficial as it allows companies to leverage the strengths of each system. An interface between the two systems can help ensure that data is shared between them, eliminating the need for duplicate data entry, reducing the risk of errors, and improving efficiency. For example, work orders created in the CMMS software can be automatically updated in the ERP software, ensuring that financial records are accurate and up to date.

Implementing an interface between the CMMS software and ERP software requires careful planning and execution. Firstly, it is essential to identify the data that needs to be shared between the two systems and ensure that both systems can support this data. Secondly, the interface should be designed to ensure that data is transferred accurately and securely, with appropriate checks and balances in place to prevent errors. Finally, it is essential to ensure that the interface is well-documented, with clear procedures for troubleshooting and resolving issues.

Using a CMMS software solution can be a better alternative to using an ERP software maintenance module for maintenance management tasks. However, integrating both systems can offer several benefits, and an interface between the two systems can help ensure that data is shared accurately and efficiently. When implementing an interface between the CMMS software and ERP software, it is essential to carefully plan and execute the integration, ensuring that data is transferred accurately, securely, and efficiently.