The Drawbacks of Manual Maintenance Management

Before delving into the benefits of CMMS software, it’s crucial to understand the limitations of manual maintenance management. Paper-based systems are inherently prone to errors and inconsistencies. Information can be easily misplaced, making it difficult to track maintenance history, manage spare parts inventories, or even adhere to a preventative maintenance schedule. Moreover, manual processes are time-consuming, requiring significant administrative effort that could be better utilised elsewhere.

Enter CMMS: A Game Changer for Manufacturers

CMMS software automates and streamlines maintenance management processes, offering a digital solution that outperforms manual methods in efficiency, accuracy, and flexibility. Here are several ways manufacturers can benefit from integrating CMMS into their operations:

Enhanced Efficiency and Productivity

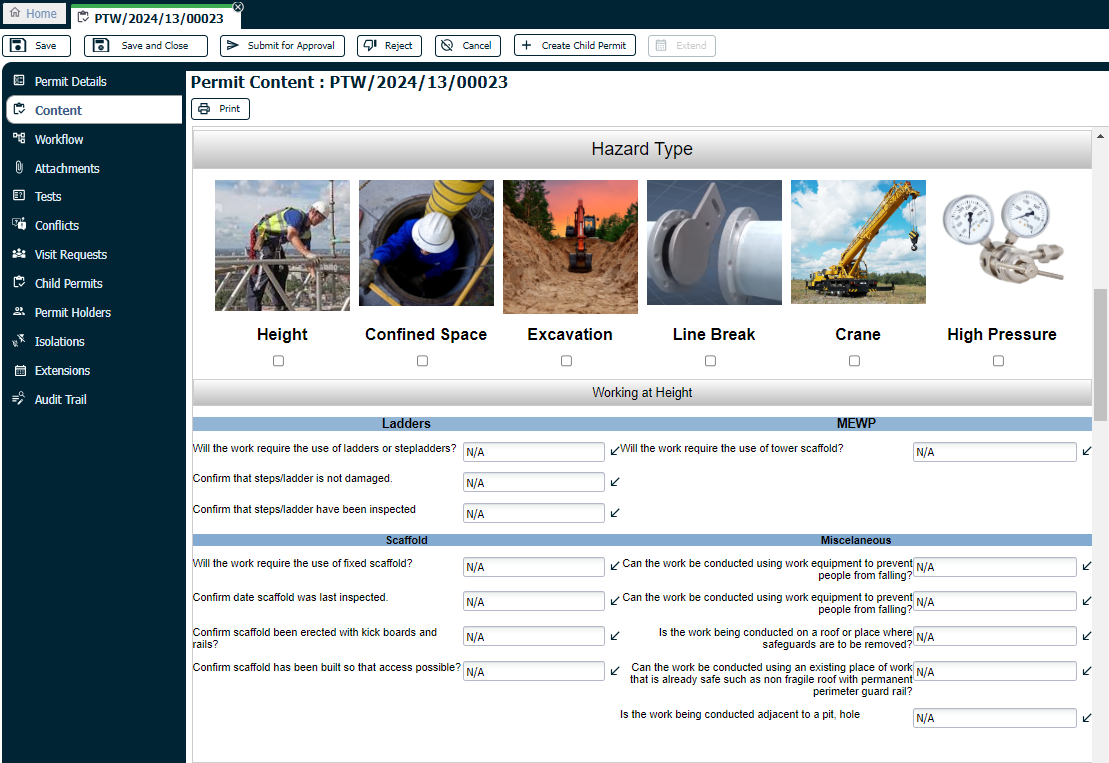

CMMS software allows for the automation of maintenance tasks, from scheduling preventative maintenance, to managing work orders and tracking progress in real-time. This automation reduces downtime by ensuring that equipment is regularly maintained and promptly repaired, leading to a significant boost in productivity.

Cost Reduction

By shifting from reactive to preventative maintenance, manufacturers can avoid the high costs associated with equipment failures and emergency repairs. CMMS helps identify maintenance needs before they escalate into costly problems, thus extending the lifespan of machinery and reducing the overall maintenance expenditure.

Improved Inventory Management

One of the more challenging aspects of maintenance management is keeping track of spare parts inventory. CMMS software provides detailed inventory management capabilities, enabling manufacturers to monitor stock levels, predict when parts need to be reordered, and reduce the capital tied up in spare parts inventory.

Data-Driven Decision Making

CMMS software collects and analyses data related to maintenance activities, offering insights into equipment performance, maintenance costs, and team productivity. This data-driven approach facilitates informed decision-making, allowing manufacturers to identify areas for improvement and make strategic investments in their maintenance operations.

Regulatory Compliance and Safety

Maintaining compliance with industry regulations and ensuring workplace safety are paramount for manufacturers. CMMS software helps manage and document all maintenance activities, ensuring that equipment is operated safely and in compliance with regulatory standards. This documentation is crucial for audits and can significantly reduce the risk of costly fines or legal issues.

Seamless Integration

Modern CMMS software solutions can easily integrate with other enterprise systems, such as Enterprise Resource Planning (ERP), Manufacturing Execution System (MES), or Supervisory Control And Data Acquisition (SCADA) software systems, creating a unified platform that enhances communication across departments and provides a comprehensive view of the organisation’s operations.

Making the Switch

Transitioning from manual to computerised maintenance management is a significant step for any manufacturer. However, the benefits of CMMS software – increased efficiency, cost savings, improved reliability, and data-driven insights – make it a worthwhile investment. By choosing the right CMMS software provider and ensuring a smooth implementation process, manufacturers can quickly reap the rewards of this transformative technology.

For manufacturers stuck in the rut of manual maintenance processes, adopting CMMS software is not just about keeping up with technology; it’s about unlocking the full potential of their operations. By making this leap, manufacturers can expect not only to optimise their maintenance activities but also to elevate their overall operational efficiency and competitiveness in the market.

More Information

If you would to learn more about how PEMAC can streamline maintenance management processes for your manufacturing organisation click here, email us at info@pemac.com or call +353 1 466 3888.

Alternatively, click the button below to request a PEMAC ASSETS CMMS quotation for your company.