Asset Performance Management (APM) is a set of practices that involve monitoring, maintaining, and optimising assets to ensure they perform at their best. With the increasing complexity of modern industrial assets, organisations require a comprehensive system to manage and maintain their assets. That’s where Computerised Maintenance Management System (CMMS) software comes in. In this blog, we’ll explore how APM and CMMS software works together to improve asset performance and achieve better business outcomes.

What is Asset Performance Management (APM)?

APM refers to the set of practices that organisations use to manage the performance of their assets, including equipment, machinery, and infrastructure. It involves monitoring, analysing, and optimising asset performance to ensure they function at their best, resulting in better business outcomes, including improved reliability, increased uptime, and reduced maintenance costs. APM is critical in industries where equipment and infrastructure downtime can have significant financial and safety implications, such as manufacturing, energy, and transportation.

APM includes various processes such as:

- Asset condition monitoring: Using sensors and other monitoring devices to measure and track asset performance, including temperature, vibration, and other metrics.

- Predictive maintenance: Using data analytics and machine learning to predict when an asset will require maintenance, reducing the likelihood of unexpected downtime.

- Maintenance planning and scheduling: Creating maintenance plans and schedules to ensure assets are serviced regularly and efficiently.

- Root cause analysis: Investigating the cause of equipment failures to identify and correct underlying issues.

What is CMMS software?

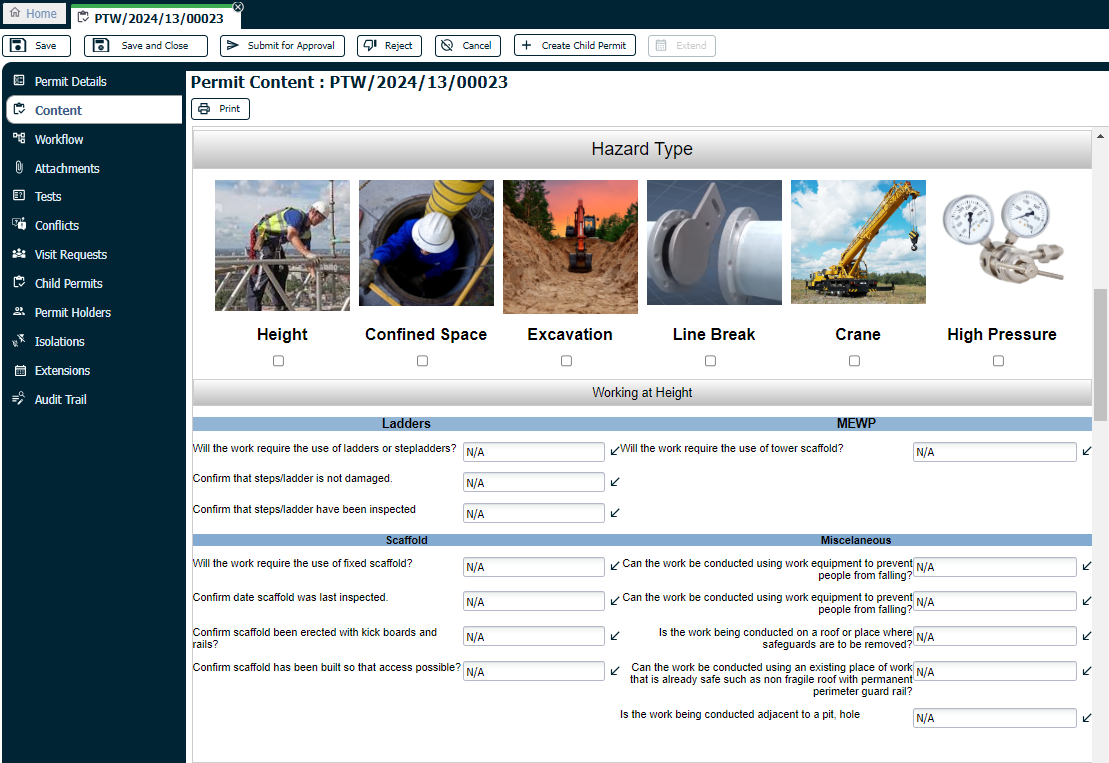

A CMMS is a software system designed to help organisations manage and maintain their assets efficiently. It enables organisations to track and manage maintenance activities, schedule preventative maintenance, and record equipment maintenance history. CMMS software also helps organisations to manage inventory and spare parts, track work orders, and manage maintenance budgets. By using a CMMS, organisations can improve their asset performance, reduce downtime, and increase equipment reliability.

How APM and CMMS software work together

APM and CMMS software are complementary systems that work together to improve asset performance. CMMS software provides organisations with the tools they need to manage maintenance activities efficiently. It allows organisations to track maintenance schedules, manage work orders, and track equipment maintenance history. APM, on the other hand, provides organisations with the tools they need to monitor asset performance, identify issues, and optimise asset performance.

By combining APM and CMMS software, organisations can create a comprehensive asset management system that includes monitoring, maintenance, and optimisation. Organisations can use APM to monitor asset performance and identify issues before they become problems. They can then use CMMS software to schedule and manage maintenance activities efficiently. By using APM and CMMS software together, organisations can improve equipment reliability, reduce downtime, and optimise maintenance activities, resulting in better business outcomes.

Benefits of using APM and CMMS software

The benefits of using APM and CMMS software together include:

- Improved asset performance: By using APM and CMMS software together, organisations can improve equipment reliability, reduce downtime, and optimise maintenance activities.

- Increased efficiency: CMMS software enables organisations to manage maintenance activities more efficiently, while APM helps identify issues before they become problems.

- Reduced maintenance costs: By optimising maintenance activities, organisations can reduce maintenance costs and improve the bottom line.

- Improved safety: APM and CMMS software can help organisations identify potential safety issues and take corrective action before they become problems.

Conclusion

Asset Performance Management (APM) and Computerised Maintenance Management System (CMMS) software are critical components of a comprehensive asset management system. By using APM and CMMS software together, organisations can improve equipment reliability, reduce downtime, and optimise maintenance activities. By implementing an APM and CMMS software solution, organisations can improve their asset performance, reduce maintenance costs, increase efficiencies and improve safety.