PEMAC’s Director of Sales, Donal Bourke discusses how CMMS and IIoT are driving Digital Transformation.

In today’s business world, the integration of technology is becoming more and more essential for success. Digital transformation has become the new norm and is a buzzword that we hear everywhere. One of the key components of digital transformation is the integration of Computerised Maintenance Management Systems (CMMS) and the Industrial Internet of Things (IIoT). These technologies are revolutionising the way businesses operate and manage their maintenance programmes.

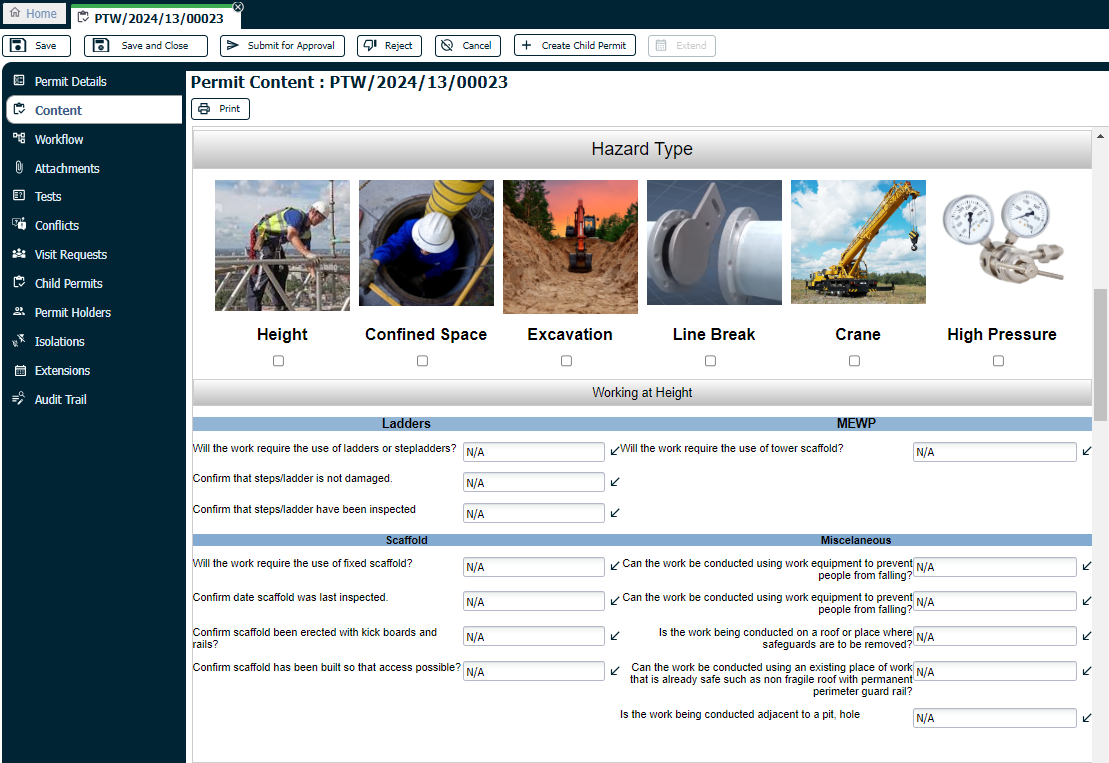

CMMS is a software solution designed to streamline maintenance management activities. It allows businesses to schedule maintenance activities, manage work orders, track equipment history, and generate reports. It provides a centralised platform for managing maintenance records and reducing downtime, extending the lifespan of critical assets. CMMS is particularly useful for asset-intensive industries such as manufacturing, energy, and utilities.

IIoT is a network of connected devices that transmit data to a central platform for analysis. It enables businesses to monitor and manage their operations in real time, providing valuable insights into equipment performance and overall efficiency. IIoT has transformed industries such as manufacturing, energy, and utilities by providing real-time data on equipment performance and enabling predictive maintenance.

When CMMS is combined with IIoT, businesses gain access to real-time data on equipment performance and maintenance needs. This combination enables predictive maintenance, which can reduce downtime and extend the lifespan of critical assets. Predictive maintenance involves analysing data from sensors and other equipment to predict when maintenance is needed. This approach enables businesses to address maintenance issues before they result in downtime or equipment failure.

The integration of CMMS and IIoT is essential for businesses that are looking to undertake digital transformation. Digital transformation is more than just implementing new technology. It involves a fundamental shift in the way businesses approach operations, with a focus on using technology to improve efficiency and productivity. The combination of CMMS and IIoT is a perfect example of this approach, providing businesses with real-time data on equipment performance and maintenance needs.

However, implementing CMMS and IIoT is not without challenges. One of the significant challenges is integration. Businesses often have a complex network of legacy systems that need to be integrated with new technologies. This integration can be time-consuming and require significant IT resources and expertise. However, the benefits of digital transformation far outweigh the challenges.

Another challenge is data management. With the amount of data generated by IIoT devices, businesses need to have a robust data management strategy in place. This strategy should include data storage, analysis, and reporting. It should also include data security protocols to protect sensitive information.

Despite these challenges, the benefits of digital transformation are significant. In addition to improving efficiency and productivity, digital transformation can help businesses reduce costs, improve quality, and increase customer satisfaction. For example, a manufacturer that implements a CMMS and IIoT solution may see a reduction in maintenance costs, an increase in equipment uptime, and improved product quality.

The adoption of CMMS and IIoT solutions is witnessing significant growth as businesses increasingly seek to capitalise on the advantages of digital transformation. Organisations across various industries are recognising the value of these technologies in enhancing operational efficiency and productivity. The increasing implementation of predictive maintenance practices and the integration of CMMS and IIoT technologies further signifies the growing importance of these solutions in driving improved maintenance management. This upward trend is expected to continue as businesses continue to realise the benefits of CMMS and IIoT in their pursuit of operational excellence.

The integration of CMMS and IIoT is transforming the way businesses approach maintenance management and digital transformation. By providing real-time data on equipment performance and maintenance needs, these technologies enable predictive maintenance and reduce downtime, extending the lifespan of critical assets. While implementation can be challenging, the benefits of digital transformation are significant and can help businesses reduce costs, improve quality, and increase customer satisfaction.