The life sciences industry is heavily regulated, with stringent standards set by agencies like the U.S. Food and Drug Administration (FDA) and the U.K.’s Medicines and Healthcare products Regulatory Agency (MHRA). Compliance with these regulations is not just mandatory but critical for ensuring product safety and efficacy.

In this blog, PEMAC Director of Sales, Donal Bourke delves into how Computerised Maintenance Management System (CMMS) software can be a vital tool for life sciences manufacturers in maintaining compliance with regulatory requirements.

The Landscape of Regulatory Requirements

Life sciences manufacturers are bound by regulations such as the FDA’s Current Good Manufacturing Practice (cGMP) and the MHRA’s standards, which necessitate meticulous record-keeping and consistent equipment maintenance. For example, the FDA’s 21 CFR Part 11 sets standards for electronic records and signatures, an area where CMMS can play a crucial role.

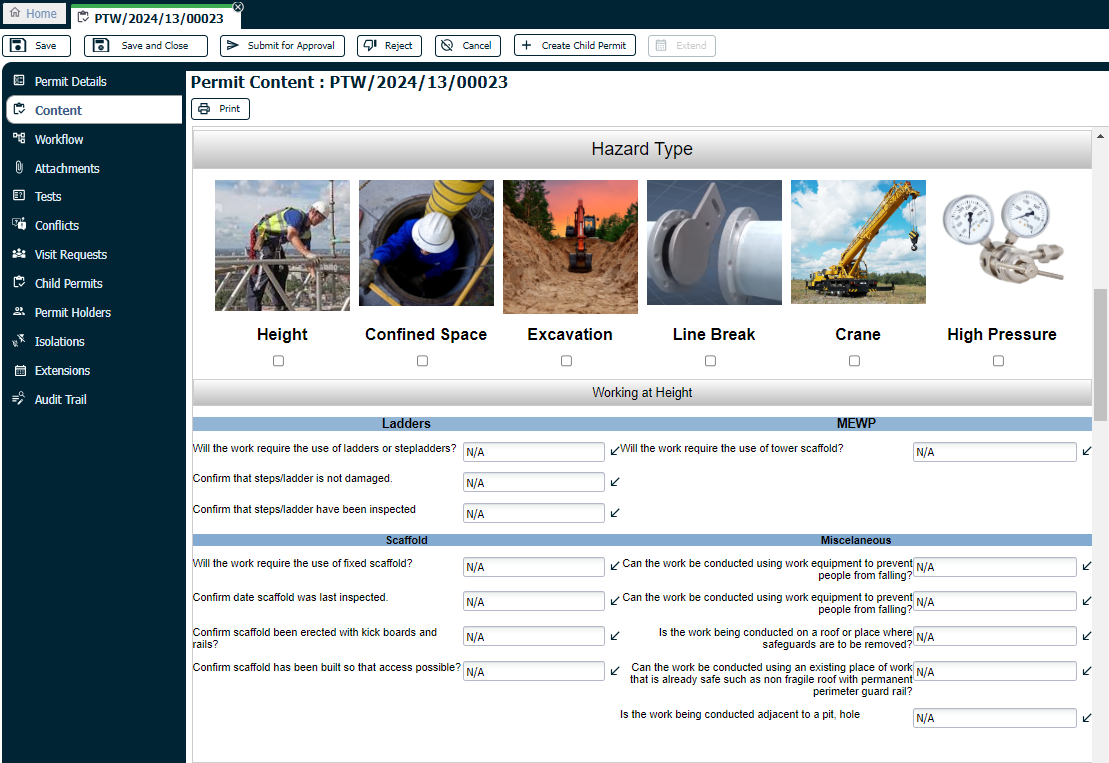

CMMS in Ensuring Compliance

CMMS software is pivotal in managing maintenance tasks in compliance with regulatory standards. Here’s how:

- Scheduled Maintenance and Record-Keeping: CMMS software automates the scheduling of maintenance tasks and keeps detailed records, which is essential for audits and inspections. According to the FDA’s Guide to Inspections of Computerised Systems in the Food Processing Industry, proper documentation is critical for compliance.

- Asset Management: Efficient tracking of equipment history, including maintenance, repairs, and performance, is facilitated by CMMS. This is in line with the FDA’s emphasis on equipment maintenance as part of cGMP (FDA’s Compliance Program Guidance Manual).

- Support for Equipment Validation: CMMS aids in documenting the equipment validation process, a key aspect of cGMP guidelines. The International Society for Pharmaceutical Engineering (ISPE) highlights the importance of validation in ensuring product quality.

- Standardising Maintenance Procedures: CMMS allows for the standardisation of maintenance procedures, ensuring uniform compliance across an organisation.

Real-World Applications and Benefits

In a practical application of CMMS in the life sciences industry, Viatris Ireland, a division of a global pharmaceutical company utilised PEMAC ASSETS CMMS to optimise its maintenance and spare parts management. The implementation of this system resulted in streamlined processes, improved maintenance scheduling, and enhanced inventory control. This led to improved compliance with regulatory standards, significantly enhancing operational efficiency.

In another real-world application of CMMS in the life sciences industry, PEMAC ASSETS CMMS software was integrated with warehouse management software (mpx/WMS) and automated storage systems (Kardex and HÄNEL) at a medical device manufacturing facility. This integration streamlined the spare parts management process, significantly enhancing maintenance efficiency and reducing manual effort. The system improved inventory control and accuracy, leading to cost savings and better compliance with regulatory requirements. This case study showcases the potential of CMMS in optimising maintenance management and ensuring regulatory compliance in the life sciences sector.

Choosing the Right CMMS for Life Sciences

In selecting a CMMS, it’s important to focus on:

- Compliance Features: Look for robust documentation and reporting capabilities.

- Scalability: Ensure that the CMMS can adapt to the growing needs of the business.

- Integration: The ability to integrate with other systems, like ERP or Quality Management Systems, is crucial.

CMMS software stands out as an indispensable tool in the life sciences industry, offering a streamlined approach to maintenance management and regulatory compliance. Its ability to automate, document, and standardise processes not only assists in adhering to FDA and MHRA standards but also drives greater efficiency and reliability in operations.

Further Information

To learn more, visit the Life Sciences section of our website, email us at marketing@pemac.com or call +353 1 466 3888.